How Builders Can Adapt to New Sustainability Mandates

For decades in the building materials sector, sustainability has been occupying a growing part of the conversation. Considering that buildings generate nearly 40% of annual global CO2, products and practices that reduce energy consumption and carbon emissions can significantly decrease the negative effects on the environment.

National, state, and local jurisdictions are taking notice, too. The California Energy Commission (CEC) updates its energy code for buildings, the Building Energy Efficiency Standards (Title 24), every three years. The latest updates to Title 24 include mandates for energy conservation related to insulation. Now, builders must meet stricter R-values for exterior walls for new construction and renovations across the state.

Simply put, new mandates are aimed at helping to reduce thermal loss through structures, which eases the reliance on HVAC systems by keeping homes at more comfortable temperatures for significantly longer periods of time.

Going, Going, Green

California is just one of the latest states to enforce stricter mandates. Energy code requirements are tightening across the country for homes and businesses alike. Based on the 2022 Building Energy Efficiency Standards Summary, one of the goals is to improve the efficiency of building envelopes for homes and commercial structures.

Therefore, builders are now required to adhere to specific R-values for above-grade walls. According to the newly updated Title 24 standards in California, mass wall exterior insulation values must fall between R-13 and R-17. Mass wall interior insulation must be between R-8 and R-13. The reason for the range can be attributed to the different climate zones throughout California.

Because of this, builders are seeking high-performance alternatives to the traditional insulation and sheathing methods (OSB and housewrap).

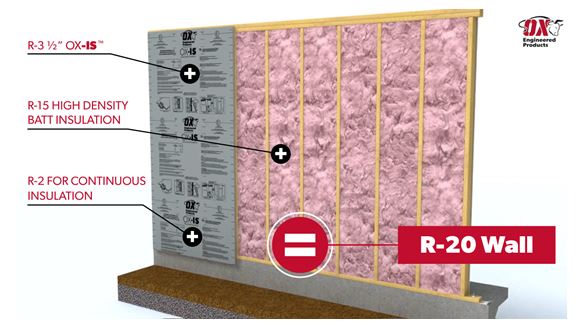

OX-IS structural insulated sheathing from Ox Engineered Products is available in three thicknesses that, by itself, offers thermal R-values ranging from R-3 to R-10. Because the insulation is continuous, an additional R-2 is automatically factored into the equation. Similarly, 1.7″ OX-IS provides a thermal R-value of R-12 before other means of insulation are considered, such as batt insulation in the wall cavity.

The building materials industry is experiencing an evolutionary shift. For building exteriors, OX Engineered Products provides a solution that empowers construction professionals to adapt to the new paradigm when it comes to energy efficiency and performance requirements.

Beyond the Golden State

Builders in California aren’t the only ones who must find alternative materials that allow them to meet the new mandates.

Back east, builders such as Michael Craddock Sr. and his son, Michael Jr., were also feeling the pressure. The Nashville-based father-son builder duo was experiencing the effects of lumber price hikes and the burden of meeting more restrictive building codes in Nashville.

The two home builders discovered OX-IS on social media at a time when costs for OSB had skyrocketed and the Nashville building code was requiring them to build homes with a minimum R-20 insulation rating.

OX-IS was their product of choice, and it allowed them to meet the needs for structural sheathing as well as the thermal insulation requirements set by the International Energy Conservation Code for numerous counties throughout Tennessee.

For the Craddocks, OX-IS went beyond generating optimal thermal performance. Using the product saves them thousands of dollars per job. In fact, Michael Sr. indicated that by choosing OX-IS, he saves $3,000 to $3,500 per house compared to using OSB and housewrap.

Simpler Than You Think

The building codes are changing. One way builders are meeting these stricter insulation mandates is by using 2×6 framing (versus 2×4 framing) and adding more materials to the exterior side of the wall. The thermal requirements can be met this way, but unfortunately, the result is a heavy, expensive wall that will likely force your project to go over budget.

With this approach, layer upon layer is needed to meet the minimum R-value requirement, which means more materials, more coordination on the job site, and ultimately more hands on deck to complete the exterior of the structure.

The alternative approach is to continue using 2×4 studs for framing to generate savings on overall lumber costs. Builders can achieve additional savings when they choose OX-IS by eliminating the need to purchase OSB and housewrap. OX-IS is a single material with all the exterior wall control layers integrated into one product: structural sheathing, continuous insulation, and air barrier, and a water-resistive barrier.

Plus, OX-IS is easy to cut, easy to lift, and easy to install. In fact, because the material is so lightweight, builders can nail or staple the product to the framing while it is on the ground and stand the entire wall section into place. This is a stark contrast compared to walls built with OSB, which are much heavier and much more difficult to safely maneuver into place once the sheathing is installed.

The New Mandate

The push for a more sustainable built environment will continue to be a driving force for builders, requiring them to use materials that make homes and commercial buildings healthier and more energy efficient.

High-performance materials that help builders meet even the country’s strictest energy codes are as accessible and affordable.

Michael Craddock put it best when assessing the impact of using OX-IS on his residential construction projects:

“We found a product that costs less with better quality,” Craddock reflected. “You can’t ask for more than that.”